In the ever-evolving world of power tools, the demand for better performance, longer battery life, and improved reliability continues to rise. As consumers and professionals alike seek tools that not only get the job done but also offer maximum efficiency, manufacturers are turning to cutting-edge technologies to meet these needs. One such innovation is the Trench MOSFET, a critical component that’s revolutionizing power tool performance. In this article, we’ll explore what Trench MOSFETs are, why they’re essential for power tools, and how they can enhance your user experience. We’ll also show you why choosing the right Trench MOSFET can be the key to optimizing your power tools’ performance.

1. Introduction

Power tools are an indispensable part of everyday life for both DIY enthusiasts and professionals. Whether you're drilling, cutting, grinding, or polishing, the performance and reliability of your tools are paramount. For manufacturers, meeting the increasing demand for better power tools means integrating advanced components that ensure efficiency, longevity, and ease of use.

One such component making waves in the industry is the Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET), specifically the Trench MOSFET. MOSFETs have been around for a long time, but the trench technology is a recent advancement that brings incredible advantages to power tools. But what exactly is a Trench MOSFET, and how can it help improve power tool performance? Let’s take a closer look.

2. What is a Trench MOSFET?

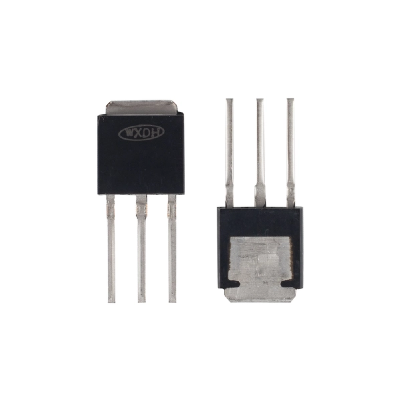

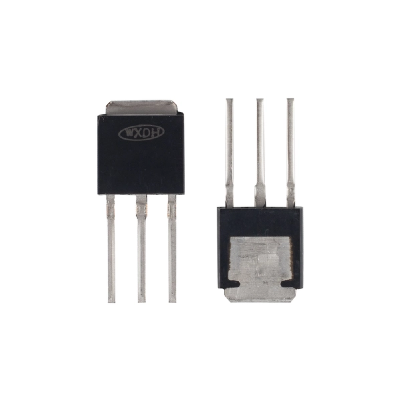

A Trench MOSFET is a type of transistor used to control the flow of electrical current in power electronics. What sets it apart from conventional MOSFETs is its unique trench design, where the gate is placed in a trench within the semiconductor material. This design allows for better control over current flow and reduces energy loss.

Key Features of Trench MOSFETs:

· Improved Efficiency: The trench structure reduces resistance and improves switching speed, resulting in higher efficiency.

· Lower Power Loss: Trench MOSFETs have significantly lower power losses compared to traditional MOSFETs, leading to better energy conservation.

· Compact Design: The smaller footprint of Trench MOSFETs allows them to be used in more compact power tool designs.

This combination of features makes Trench MOSFETs an ideal choice for power tools, where efficiency and durability are crucial.

3. Why Trench MOSFETs Are Essential for Power Tools

Power tools are all about performance, and their performance hinges on how efficiently they can convert energy from the power source to the working mechanism. Trench MOSFETs play a crucial role in this conversion by enabling faster switching and reducing energy loss.

Energy Efficiency

In power tools, the ability to quickly convert electrical energy into mechanical power without wasting energy as heat is key to longer runtimes and better battery performance. Trench MOSFETs excel in this area due to their low on-resistance and high-speed switching capabilities. This translates into less power lost during operation, making power tools more energy-efficient.

Durability and Reliability

The superior heat dissipation properties of Trench MOSFETs enhance the overall durability of power tools. Power tools often operate in demanding environments, and efficient heat management ensures that components like MOSFETs stay within optimal temperature ranges, preventing overheating and failure. This longevity is essential for both consumer satisfaction and the tool’s operational efficiency over time.

Compact Design

The compact nature of Trench MOSFETs means that manufacturers can design power tools that are not only more efficient but also smaller and lighter. This is especially important for portable tools, where reducing the size and weight without sacrificing power is a key design challenge.

4. Applications of Trench MOSFETs in Power Tools

Trench MOSFETs are used in a wide variety of power tools, where their ability to handle high currents and reduce energy loss directly impacts performance. Here are a few examples of how they improve the efficiency and functionality of power tools:

Cordless Drills and Screwdrivers

Cordless drills and screwdrivers are some of the most common power tools used in everyday tasks. With Trench MOSFETs, these tools can run longer on a single charge, ensuring that users can complete more tasks before needing to recharge. Moreover, the reduced power loss means less strain on the battery, which in turn prolongs battery life.

Saws and Grinders

For tools that demand high power output, such as saws and grinders, Trench MOSFETs help manage energy flow more effectively. They allow for faster, more consistent operation, even under heavy loads, ensuring that the user can complete tasks more efficiently. The higher efficiency also reduces the likelihood of overheating, keeping the tool running smoothly during long hours of use.

Impact Wrenches and Rotary Hammers

These high-power tools benefit significantly from the use of Trench MOSFETs. The high current-handling capability of Trench MOSFETs allows them to deliver more torque and power while minimizing energy waste. This means users experience better overall performance, especially in demanding applications like construction or automotive repair.

5. How Trench MOSFETs Enhance User Experience

The benefits of Trench MOSFETs extend beyond just performance improvements; they also enhance the overall user experience in several ways.

Faster Performance

By enabling faster switching, Trench MOSFETs allow power tools to perform tasks more quickly. Whether it's drilling through tough materials or cutting through metal, the faster and more efficient energy transfer ensures that tasks are completed in less time, boosting productivity.

Longer Battery Life

One of the most significant advantages of using Trench MOSFETs in power tools is their ability to prolong battery life. With less energy wasted as heat, the battery can last longer between charges, allowing users to work uninterrupted for extended periods.

Heat Management

The efficient heat dissipation offered by Trench MOSFETs ensures that power tools remain cool even during extended use. This prevents tools from overheating, which can otherwise cause damage to both the tool and the user. A cooler tool is not only more comfortable to use, but it also prevents unnecessary wear and tear on internal components.

6. Why Choose Trench MOSFETs for Your Power Tools?

Trench MOSFETs offer a range of advantages that make them an ideal choice for both consumers and manufacturers.

Cost-Effectiveness

Though Trench MOSFETs may have a higher upfront cost, their long-term benefits—such as better energy efficiency, longer battery life, and greater durability—make them a cost-effective choice for power tools. Reduced maintenance and fewer repairs also contribute to overall savings.

Technological Innovation

Trench MOSFETs represent the cutting edge of power tool technology. By incorporating these advanced components into their designs, manufacturers can ensure their products remain competitive and meet the growing demands of consumers who expect the latest innovations.

Improved Safety

Efficient power regulation is crucial for safety, especially in tools that handle high power. Trench MOSFETs ensure that power is delivered smoothly and safely, preventing overheating and reducing the risk of accidents caused by electrical failure.

7. Conclusion

As the power tool industry continues to evolve, the demand for more efficient, reliable, and compact tools is only going to increase. Trench MOSFETs offer a solution to these challenges by improving energy efficiency, reducing power loss, and enhancing overall tool performance. Whether you’re a DIY enthusiast or a professional tradesperson, tools equipped with Trench MOSFETs can help you get the job done faster, more efficiently, and with less downtime.

We are committed to providing high-quality Trench MOSFETs for a range of power tool applications. If you're looking to upgrade your tools for better performance and longer battery life, get in touch with us today. Let us help you choose the perfect solution for your needs!